LTS-100TM Laser Temperature Sensor

Non-intrusive Thermometry for Power Plant, Process Monitoring, and Aerospace Applications

Introduction

MetroLaser, Inc., an innovator in the field of laser-based instrumentation, has developed the LTS-100TM laser temperature sensor to enable measurement of gas temperatures up to 4000 °F with proper calibration.

This laser-based sensor is well-suited for temperature measurement in the harsh environments found in power plants and aerospace, since the sensor is non-intrusive and has low sensitivity to particulates and other obscurities.

MetroLaser’s goals in marketing the LTS-100TM are to improve the reliability and quality of traditionally challenging high temperature measurements.

System Overview

LTS-100TM operation is based on absorption of infrared light by hot H2O molecules, which is dependent on both gas temperature and light wavelength. By measuring the absorption that occurs at different laser wavelengths, the system can obtain the gas temperature.

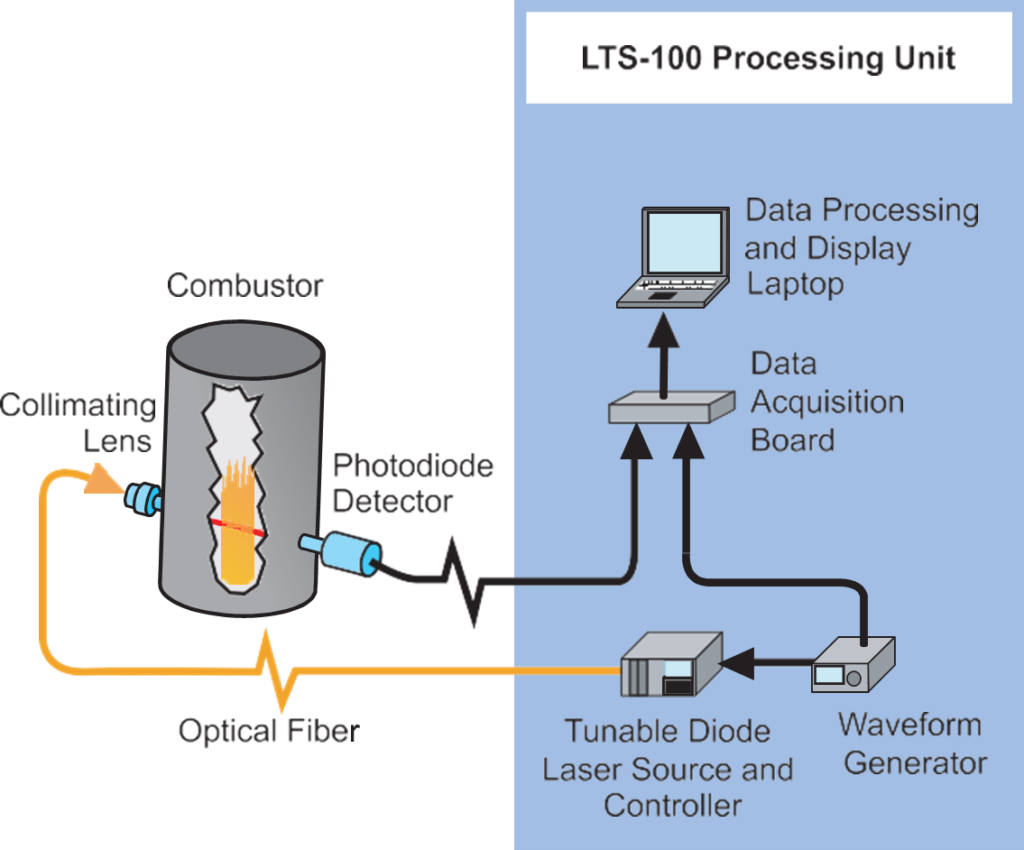

At left is a schematic of the LTS-100TM in a combustion temperature measurement application. A tunable diode laser generates a laser beam at a wavelength that is precisely modulated by a waveform generator. The beam is transmitted down the length of an optical fiber and enters the combustion chamber through a collimating lens and optical access port. A photodiode detector, mounted on the opposite side of the chamber, receives the transmitted laser light through a second optical access port.

The photodiode detector output is sent to a laptop computer via a data acquisition board. Processing software on the laptop computes the gas temperature based on principles of absorption spectroscopy.

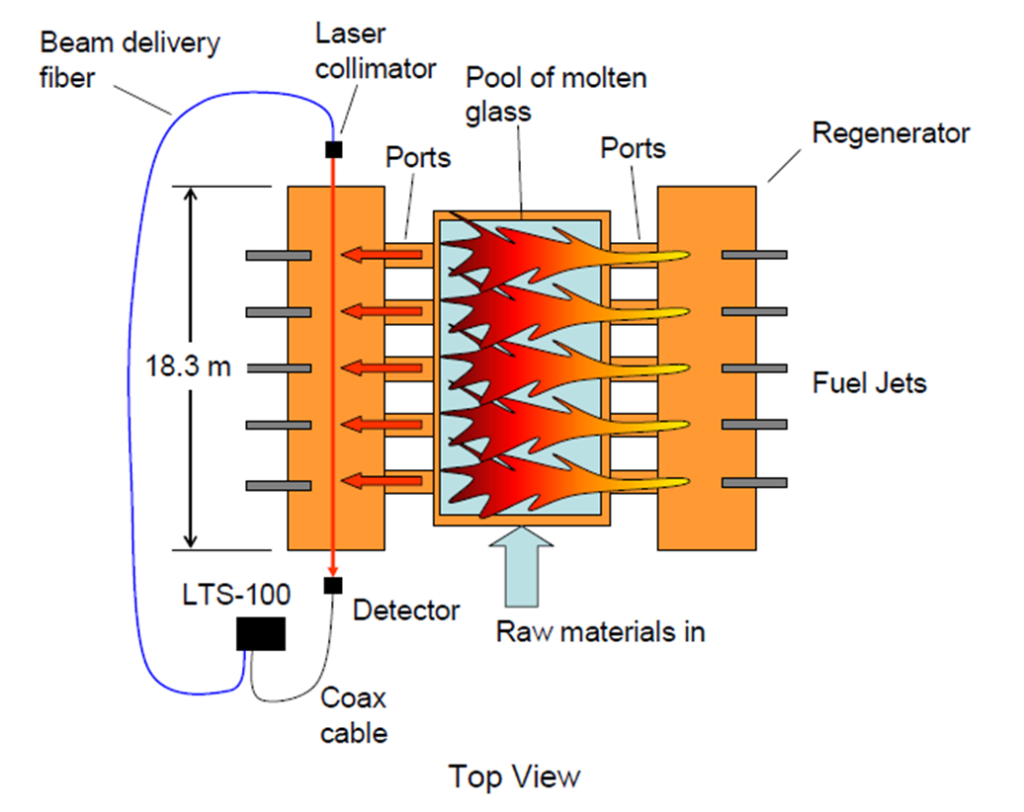

The LTS-100TM has been applied to a range of applications, including rocket testing, coal fire power plants, and glass furnaces. At right is a setup that was used for temperature and H2O concentration measurements in a glass furnace, in which a fiber optic was used for delivering laser light to the measurement region. The use of the fiber optic allows the processing unit to be placed a safe distance from the furnace.

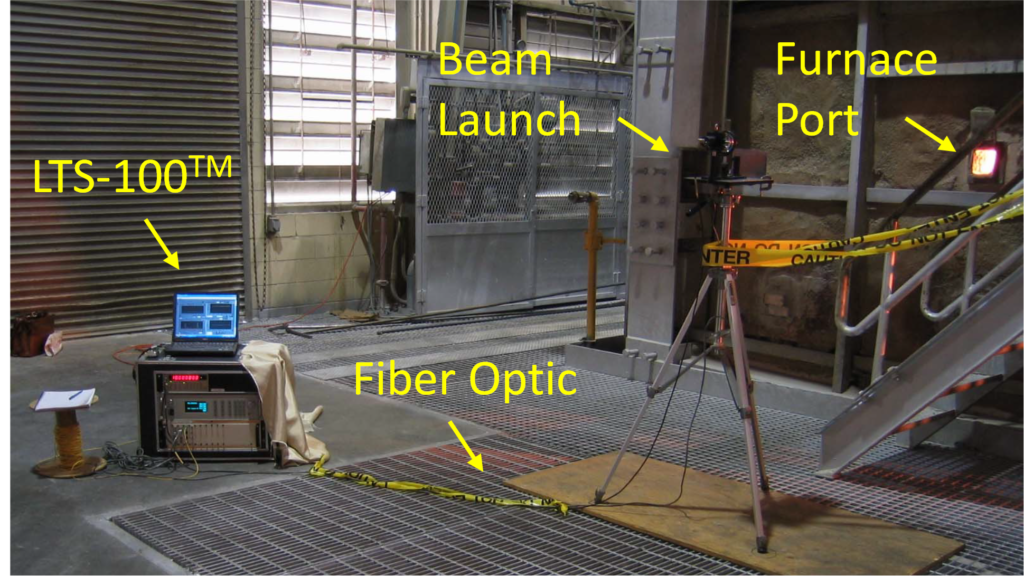

A photo of the setup in the glass furnace is shown on the right. The fiber optic enabled complete flexibility in the placement of the LTS-100TM processing unit. The beam launch unit can be seen mounted on a tripod, from which it projected a beam into the furnace port. A detector on the opposite side of the furnace received the beam (not shown).

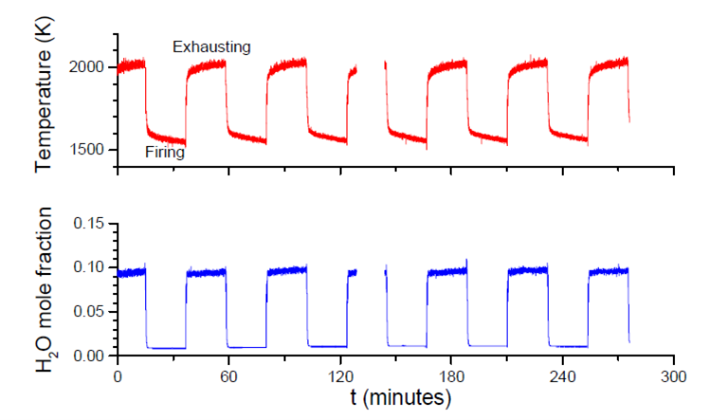

The plot at right shows example time traces of gas temperatures and H2O concentrations measured by the LTS-100TM in a glass furnace, revealing the firing and exhaust cycles of the furnace’s periodic operation.

The gas temperature is obtained from the ratio of measured absorbances at two wavelengths and the H2O concentration is obtained from the absorption strength.

Interpretation of LTS-100 Temperature Measurement

The temperature computed by the LTS-100TM is the path-averaged temperature along the beam path. For applications where temperature distributions are of interest, the LTS-100TM system can be modified for multi-beam capability. In the multi-beam configuration, the data collected from multiple path-averaged signals are combined using tomographic techniques to determine the temperature distribution.

For more information, see: https://ieeexplore.ieee.org/document/1597864

Simple, Robust Design

The wavelengths of the LTS-100TM sensor are closely spaced and fall within the band used by telecommunications equipment. This allows a single communications-grade laser source to be used, leading to a simple, robust measurement system.

Insensitive to Obscurities

Obscurities in the beam path that may be caused by soot, dirty windows, or broadband absorption by other molecules are not a problem. Such obscurities have similar effects on each absorption feature, such that the absorption ratio remains constant. As a result, the LTS-100TM is essentially unaffected by these interferences.

High Temperature Capability

The highest measurable temperature is limited solely by the absorption characteristics of H2O molecules, since there is no physical contact with the gases being measured. Currently, the system has been validated up to 2800 °F, but future validations are planned for temperatures up to 4000 °F.

Physical Robustness

The laser beam is transmitted through a fiber-optic line that can be essentially unlimited in length. This property enhances the mechanical robustness of the system by allowing physical separation of the processing unit from the harsh combustion environment.

Furnace Exit Gas Temperature measurement

Monitor and control furnace exit-gas temperature (FEGT) during start-up and operation. Maintain FEGT below ash fusion temperature to minimize slag build-up.

Fireball centering

Monitor temperature near furnace walls to ensure that flames do not impinge on walls.

Selective Catalytic Reduction

Improve SCR operation through measurement of SCR inlet temperature distribution (with multi-beam option and future low temperature capability).

Aerospace

Measure temperatures of combustion products to monitor hot spots streaking.

Measurement Range*:

Precision:

Accuracy:

Sample Rate:

Pathlength*:

1160 to 4041 °F

+/- 18 °F

+/- 90 °F

200 Hz

1 to 33 ft

* Temperatures higher than 2800 °F and pressures greater than one atmosphere require validation that is currently under development.

Pricing for purchase and leasing for single-beam and multi-beam systems will be available upon request.

Optical housings for additional measurement locations are priced separately. The housings isolate optical components against environmental conditions. Active removal of deposits on optical access ports will require additional components. Contact MetroLaser for pricing information on these items.

Lease payments will be fully credited towards the purchase of a system. A one-year warranty against manufacturing defects in materials and workmanship is included. Delivery time is three months.

For more information, please contact:

Tom Jenkins

tjenkins@metrolaserinc.com