Technologies

Thermographic Phosphors for Temperature Measurement of Turbine Blades

MetroLaser has developed a diagnostic system for accurate temperature measurements on the surface of a rotating turbine blade in an operating engine using laser-induced excitation of thermographic phosphor coatings on the blades. Temperature measurements between 512 and 764 °C are demonstrated on a moving turbine blade with a probe mounted to the engine at speeds of between 28,000 and 32,750 RPM. The method involves measuring the time decay of laser-induced luminescence from two different phosphor coatings, each applied to a different turbine blade. The phosphors are each excited by a 10-ns laser pulse at a wavelength of 355 nm, and temperature is obtained from the ratio of the luminescence decay curves. The luminescence occurs primarily within a narrow spectral band, so unwanted background emission from gases, particles, and hot surfaces within the engine can be suppressed to a large degree by spectral filtering. The data show high signal-to-noise ratios, and the measured temperatures are within the expected range for this engine.

Results are shown below from experiments conducted in a Williams International FJ44-4A turbofan aircraft engine using a specially designed probe, shown in Figure 1. This probe was developed to convey the laser beam to a measurement spot on the blade, and to collect the resulting luminescence. The effects of motion are compensated for by taking the ratio of signals from two different phosphors, one with a short lifetime relative to the blade passing duration, and one with a long lifetime. Interference from naturally present luminosity of the gases and hot surfaces in the engine is avoided by selecting phosphors with short wavelength emission bands.

Four of the turbine blades of the high pressure turbine disk, which normally utilizes uncoated blades, were coated with 25 μm-thick phosphor layers. Two types of phosphor coatings were used, a short luminescence lifetime (YAP:Tm) coating deposited by electron beam physical vapor deposition (EB-PVD), and a long luminescence lifetime (YAG:Dy) coating deposited by the solution precursor plasma spray method. To enable the coatings to adhere well, a 200 μm-thick thermal barrier coating of yttria-stabilized zirconia, deposited by EB-PVD, was applied first. The coated blades were arranged in pairs of two, with the short lifetime and long lifetime phosphors placed adjacent to each other. The probe was inserted radially into the turbine case and protruded a few millimeters into the flow path between the high and low pressure turbine disks. It viewed the suction side of the high pressure turbine blades with a standoff distance of about 25 mm.

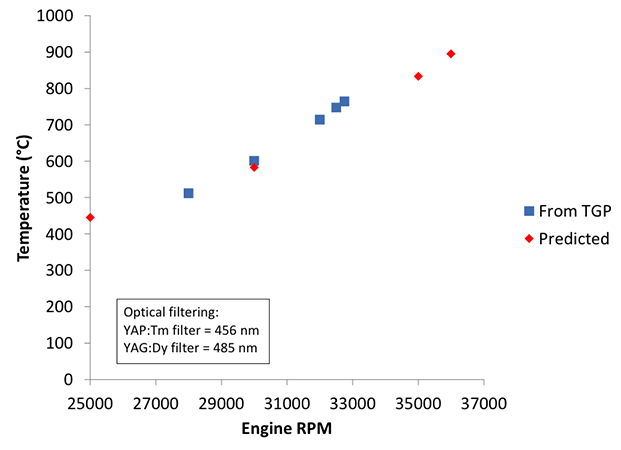

Figure 2 shows temperatures obtained by the thermographic phosphors (TGP) plotted together with predicted temperatures over a range of engine speeds.

Figure 2 shows good agreement between the temperatures obtained from the thermographic phosphor measurements and the manufacturer’s predictions. The TGP data show the same trend as the predictions, but about 25 °C higher in magnitude.